Why Rotary DIP Switches Matter: Reliable Configuration for Modern Electronics

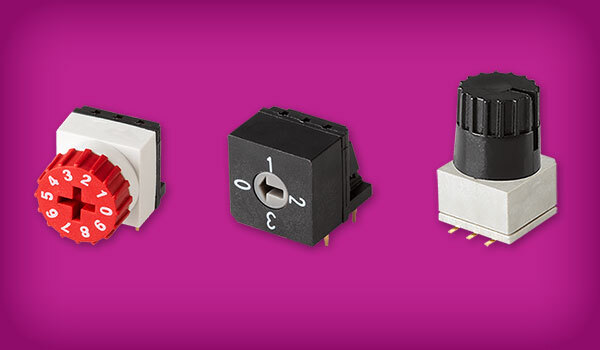

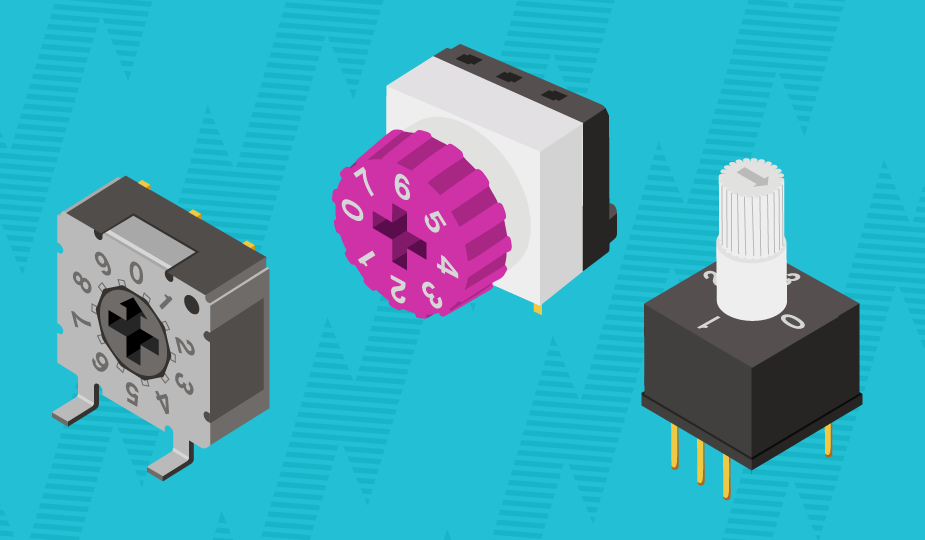

What are Rotary DIP Switches?

A rotary DIP (or Dual In-line Package) switch is a small mechanical device that outputs a coded value, most often in BCD (binary coded decimal) or hexadecimal. BCD encodes decimal digits (0–9) in binary form, while hexadecimal encodes values from 0–15 using digits and letters (0–F). Each position on the switch corresponds to a specific digital output, which can be read directly by a microcontroller or control circuit. Because the switch is mechanical, the selected position remains in place even if the device is powered off, making it a dependable choice for persistent settings. This eliminates the need for complex user interfaces or dedicated firmware menus. For instance, a 16-position rotary DIP switch has sixteen unique coded values, which can then be assigned to functions such as network addresses, timer settings, or device modes. We went into more depth about rotary DIP switches and their encoding schemes in our DIP Switches 101 video.

Rotary DIP switches may not always get the same attention as microcontrollers or sophisticated software interfaces, but they remain one of the most practical ways to configure hardware. Unlike digital menus or cloud-based controls, these compact mechanical selectors offer a set-and-forget solution. Once adjusted, they hold their value without risk of firmware corruption or accidental reprogramming.

Same Sky provides a range of rotary DIP switches designed specifically for engineers who value compact form factors and reliable functionality. Options such as raised actuators and removable caps make it easier to change settings in the field, either by hand or with a tool, while maintaining long-term stability. We specifically offer models with a raised actuator and removable caps to facilitate easier selections or adjustments without tools.

Interested in more switches content? Check out our other blog topics:

- What Are DIP Switches? A Guide to Types, Functions, and Uses

- Fundamentals of Switches: A Guide to Types, Uses, and Selection

- Slide Switches Selection Guide: From Form Factor to Function

- Tactile Switches Explained: Selection, Design Tips, and How They Work

- Push Button Switches: Types and Selection Tips for Engineers

Why Use Rotary DIP Switches?

While modern electronics increasingly rely on programmable software, rotary DIP switches continue to stand out for their simplicity and reliability. They deliver precise, repeatable results. Setting the switch to position five will always yield the same coded value without risk of drift or interpretation errors. Because the configuration is physical rather than digital, there is no chance of accidental reprogramming or software glitches altering the setup.

Field technicians also appreciate the convenience. Adjustments can be made with nothing more than a screwdriver or even just fingers if using one of our raised actuators. This removes the need for laptops, programming cables, or specialized software tools. From a design perspective, rotary DIPs reduce development costs by eliminating the need for a display or firmware interface, and they also help conserve valuable microcontroller pins by consolidating multiple inputs into a single selector.

Where Can I Use Rotary DIP Switches?

Rotary DIP switches have proven their value across a wide variety of industries. They are used anywhere reliable, repeatable hardware configuration is needed without relying on digital programming tools. Their versatility is what makes them a trusted choice across energy systems, industrial automation, retail automation, and safety equipment, leading to a forecast of large market growth over the next few years.

Rotary DIP Switches in Energy and Power Systems

In energy and power applications, rotary DIP switches are commonly used to set communication addresses, operating modes, and output limits. Solar inverters, EV chargers, and battery storage systems often incorporate rotary DIPs for these functions, allowing quick adjustments in the field without a computer or firmware update. The mechanical nature of the switch ensures that once a position is selected, it remains fixed even through power cycles, an ideal feature for equipment that must perform consistently in demanding environments. Specific examples include:

- Selecting the operation mode of battery storage equipment

- Setting the communication address (ID) of a solar inverter

- Defining output current limits in EV chargers

- Assigning individual IDs to each solar inverter in a group for centralized control

- Defining unique IDs for each battery storage module or rack

- Identifying each EV charger unit within a larger charging network system

Rotary DIP Switches in Industrial Automation

In industrial and factory environments, rotary DIP switches provide simple configuration for programmable logic controllers and motor controllers. They allow engineers and technicians to assign device addresses, select control modes, or adjust sensitivity levels without additional software or display interfaces. Each position delivers a defined electrical output, assuring that system behavior will remain stable and predictable. Their durable mechanical design also stands up to vibration, dust, and temperature variations that are common in industrial environments. Specific examples include:

- Channel address configuration for terminal blocks

- Modbus or RS-485 address setting for controllers and gateways

- Node ID assignment between multiple automation devices

- Selecting sensitivity levels (0–9) for sensors

- Setting motor speed or current limits in predefined steps

- Adjusting limit switch activation ranges

Rotary DIP Switches in Smart Retail and Commercial Systems

Self-service and retail automation systems rely on rotary DIP switches for quick, consistent setups. Applications include parcel lockers, vending machines, and parking systems, where switches are used to assign identification numbers, timer values, or even acceptable retry counts. By using a physical selector rather than software, installers can deploy or reconfigure equipment quickly. Specific examples include:

- Assigning module numbers to smart parcel lockers

- Setting network IDs for self-service kiosks or unmanned refrigerators

- Configuring terminal location numbers in smart parking systems

- Setting auto-lock delay after door opening in unmanned systems

- Limiting the number of product dispenses in vending machines

- Configuring retry attempts or logic parameters in unmanned checkout devices

Rotary DIP Switches in Security and Safety Equipment

Rotary DIP switches are also common in alarm panels, CCTV cameras, and fire alarm repeaters. They allow installers to set device IDs, groupings, or response modes with exact repeatability. The clear, mechanical position of each selector reduces the chance of programming errors and allows quick visual verification or inspection, especially important in safety or security systems. Specific examples include:

- Assigning unique zone IDs to alarm panels or detectors

- Setting camera IDs or channels for multi-camera CCTV systems

- Configuring response delay times in intrusion alarm controllers

- Selecting alarm sensitivity levels for motion or vibration sensors

- Defining communication addresses for fire alarm repeaters or modules

- Choosing system mode (test, normal, maintenance) in safety control units

How to Use Rotary DIP Switches

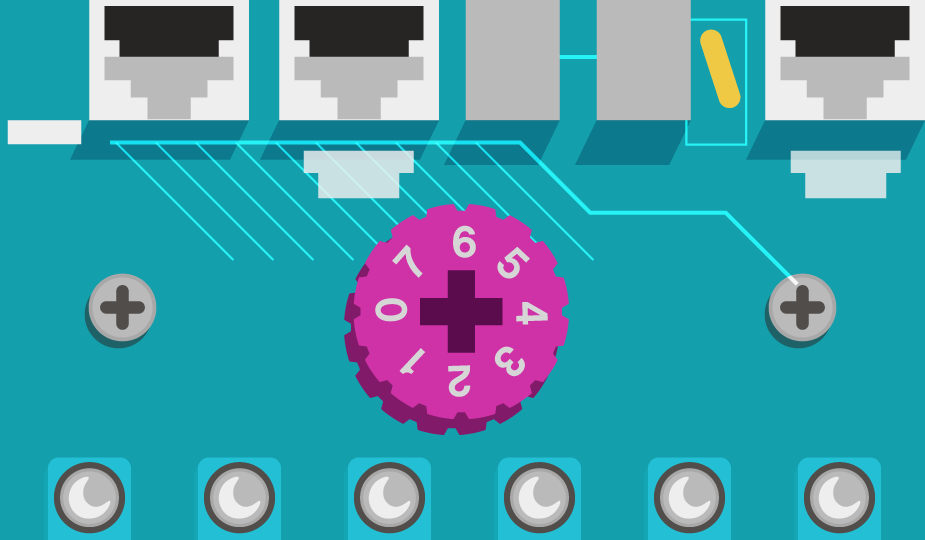

Integrating a rotary DIP switch into a system is straightforward, but there are important considerations that ensure reliability and usability. The first step is to select the correct coding scheme, whether it is BCD or hexadecimal, based on the required values. Designers must also map the output pins properly to the microcontroller or other devices during PCB layout.

Placement matters as well. Switches should be in an accessible area with sufficient clearance for adjustment, space for large hands, and, depending on the application, potentially gloves. Labels on the PCB or enclosure help end users understand what each setting controls. Finally, it is essential to observe the voltage and current ratings of the switch to ensure safe operation.

Selecting the Correct Rotary DIP Switches

Choosing the correct rotary DIP switch depends on the application and the environment in which it will be used. Engineers and designers need to consider the number of available positions, the size of the footprint, and the preferred mounting style, whether through-hole for durability or surface-mount for automated assembly. Environmental protection may also be critical if the device will be used in dusty or moisture-prone environments. Same Sky offers several IP rated rotary DIP switches for rugged applications.

Actuator design is another factor. Raised actuators make adjustments by hand much easier, while recessed versions provide more protection against accidental changes. Same Sky offers a wide variety of options across these categories, making it possible to tailor the switch precisely to both the design and the intended field conditions.

Conclusion

Rotary DIP switches continue to prove their worth as a simple, durable, and cost-effective solution for configuring electronic devices. Their role in solar inverters, EV chargers, industrial automation, and smart retail underscores their adaptability and staying power. With global adoption rising and US markets expanding rapidly, they remain essential components in both established and emerging applications.

Same Sky is committed to supporting this growth by delivering high-quality DIP switches tailored to the needs of modern design. Whether you are building energy systems, industrial equipment, or next-generation retail infrastructure, our rotary DIP solutions can help you simplify design, reduce costs, and deliver reliable performance.

Key Takeaways

- Rotary DIP switches provide stable, repeatable hardware settings without reliance on software.

- They are widely used in energy, automation, retail, and security applications, with adoption growing globally and in the US market.

- Same Sky offers compact rotary DIP switches, including models with raised actuators and removable caps for ease of use.

- Global industry trends indicate continued growth for applications that benefit from reliable, cost-effective hardware configuration.