Fundamentals of Switches: A Guide to Types, Uses, and Selection

Switches are not only prevalent in every aspect of daily life, but they are also nearly as diverse as they are numerous. Besides the basic differences between mechanical or electrical operation and manual or electronic actuation, there is a nearly endless variety in size, shape, inputs, outputs, interfaces, and features. From switches barely large enough to see with the unaided eye to switches too large to move without specialized equipment - the options may seem endless. While all switches have their strengths and weaknesses, at times, the only true difference between using one type of switch and another is the aesthetic and the user interface style desired. Yet with a foundational understanding of the different switches available, a product designer can make informed decisions on what will not only work best in form but in function.

Electronic switches that are based on BJTs, MOSFETs, IGBTs, or other semiconductor designs are becoming more popular due to decreasing costs and increasing features. However, they are still not the ideal solution for the majority of switching applications, and switches that rely on mechanical contacts opening and closing still dominate the market. Besides the operation, switches can be actuated, changed from one state to another, either manually or electronically. Manual actuation is most often done by a physical operator whereas electronic switches typically operate based on pressure, temperature, time, or any variety of sensor inputs. To reduce the scope of this switches topic to a manageable level, physically operated and actuated switches will be the focus of this post. Shop Same Sky's full range of switches.

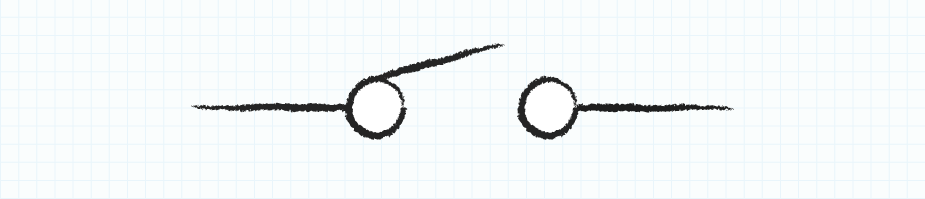

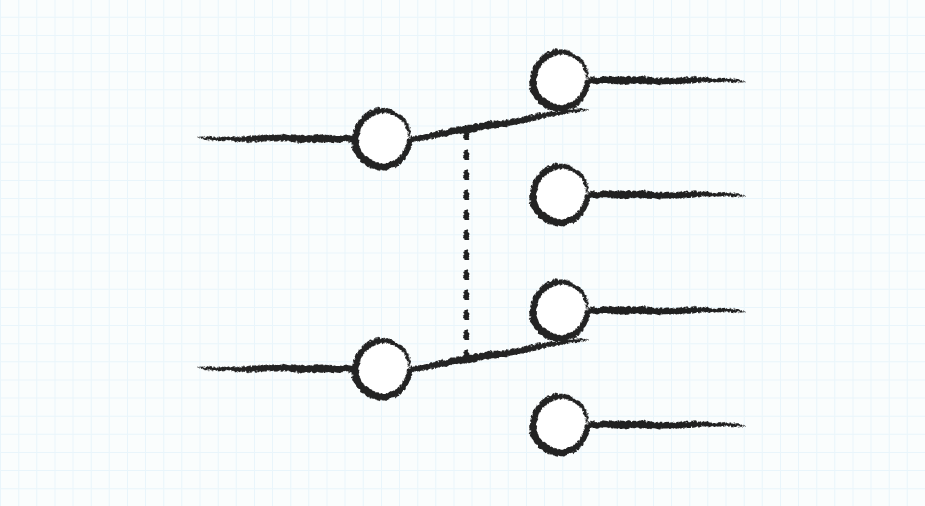

What Are Poles and Throws for Switches?

Any discussion about switches will require an understanding of poles and throws. In short, poles indicate how many circuits a single switch can control. Throws, on the other hand, indicate how many contacts the switch can choose between. This concept is best understood with simple illustrations.

What is an SPST Switch?

As seen with a switch with only a single pole and a single throw, conveniently called SPST, there is only one circuit that can be controlled, and the switch only opens and closes a single contact. Compare that to a switch with a single pole but a double throw, SPDT.

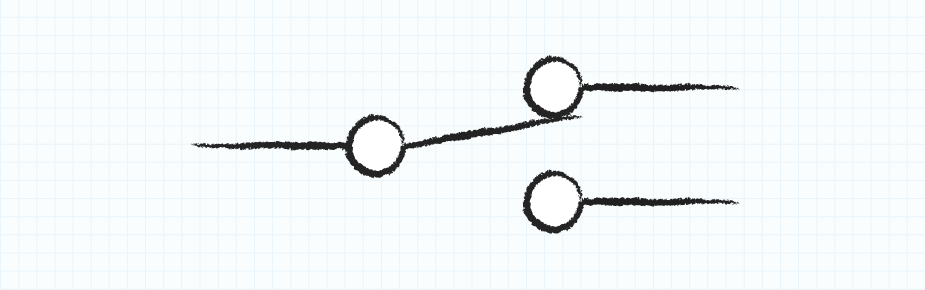

What is an SPDT Switch?

In the SPDT switch, there is still only one circuit to be controlled but the switch can change between two different contacts. With an SPDT switch, there is no restriction to simply open and close a circuit but to instead redirect the circuit.

What is a DPDT Switch?

With a double pole, double throw, or DPDT switch, there are both two circuits that are controlled by this single switch and both switches have two contacts that they switch between. While SPST, SPDT, DPST and DPDT are the most common switch configurations found, there is no theoretical limit to how many poles and throws a switch has. To simplify matters, if there are more than two poles or throws, the acronyms use a number in place of the ‘S’ or ‘D’. For example, a switch that offers three poles and six throws will likely be advertised by its manufacturer as a 3P6T switch. A single pole with five throws could be indicated as SP5T. This nomenclature is extremely common and a solid understanding of both the terms and their representations will be crucial in selecting the ideal switch for an application.

Features to Consider When Selecting a Switch

In addition to the poles and throws of a switch, there are many features that distinguish between the different varieties produced by manufacturers. Below is an extensive but not all-inclusive list of common features to consider.

Size

Switches come in all shapes and sizes—from ultra-compact components smaller than a grain of rice to large industrial models that require two hands or heavy equipment to operate.

- Small switches are ideal for embedded and portable devices where space is limited.

- Large switches are typically used in high-power or industrial environments where gloved operation or high durability is needed.

Default State (Momentary vs. Maintained)

Understanding a switch’s default state is essential when designing for user interaction or automated response.

- Momentary switches return to their default state once force is removed.

- Normally Open (NO): Circuit is open by default, closes when pressed.

- Normally Closed (NC): Circuit is closed by default, opens when pressed.

- Maintained switches remain in their new state until manually changed again.

Number of Positions

This refers to how many individual switching elements are integrated into a single component. It's a common point of confusion with “throws,” but positions describe separate actuators or circuits within one switch unit. Example: A 4-position DIP switch contains four independently actuated switches in one package.

Mounting Options

Switches offer multiple mounting formats to accommodate different mechanical and electrical requirements.

- Through hole mounting: Leads pass through the PCB and are soldered on the opposite side.

- Surface mount (SMT): Components are soldered directly onto PCB pads.

- Panel mount: Used for front-panel user interfaces and enclosures.

- DIN rail mount: Common in industrial automation environments.

Pitch (lead spacing) is especially critical for through hole designs, particularly when designing for breadboards or tight PCB layouts.

Actuation Options

Switch actuation affects usability and accessibility.

- Manual vs. Electronic: Switches may require physical force or be triggered electronically.

- Tool-activated vs. Glove-compatible: Some require precision tools; others are designed for rugged environments.

- Raised vs. Flat actuators: Raised actuators are easier to press; flat types may be recessed or flush for tamper-resistance or aesthetics.

Current and Voltage Rating

All switches are limited by their electrical ratings, which must be matched to the demands of the circuit.

- Voltage rating: Maximum voltage the switch can safely handle.

- Current rating: Maximum current the switch can carry without overheating or degrading.

These ratings are not always proportional—ensure both are suitable for your use case independently.

Environmental Factors

In harsh or mission-critical environments, switch durability matters just as much as electrical performance.

- Ingress Protection (IP) ratings: Define resistance to dust and water.

- Vibration resistance: Important in automotive, aerospace, or machinery settings.

- Vandal-proof housings: Designed to withstand tampering or impact in public installations.

Common Types of Mechanical Switches

Although there is a wide variety of switches available, most mechanically actuated switches fall into a few core categories. The examples below are manually operated and commonly used in compact, portable, or embedded systems, but their use is not limited to these applications.

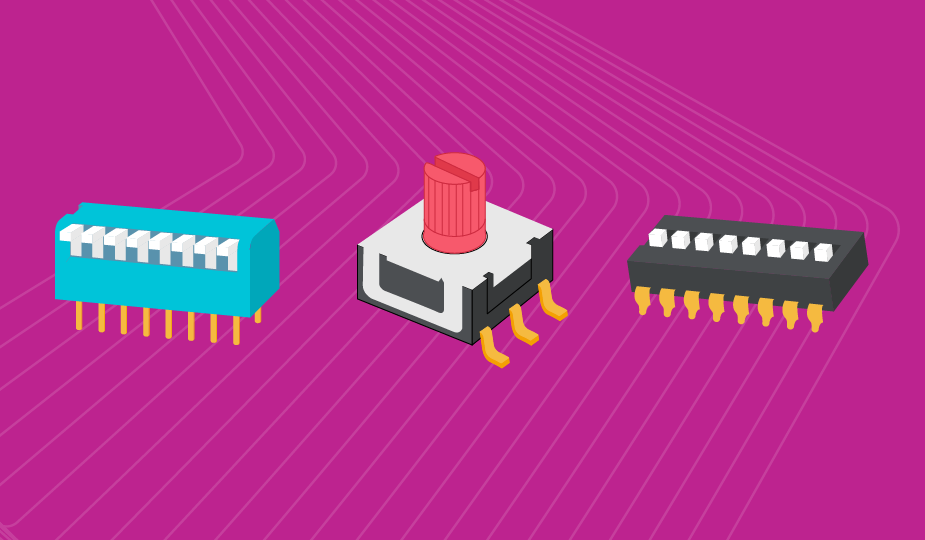

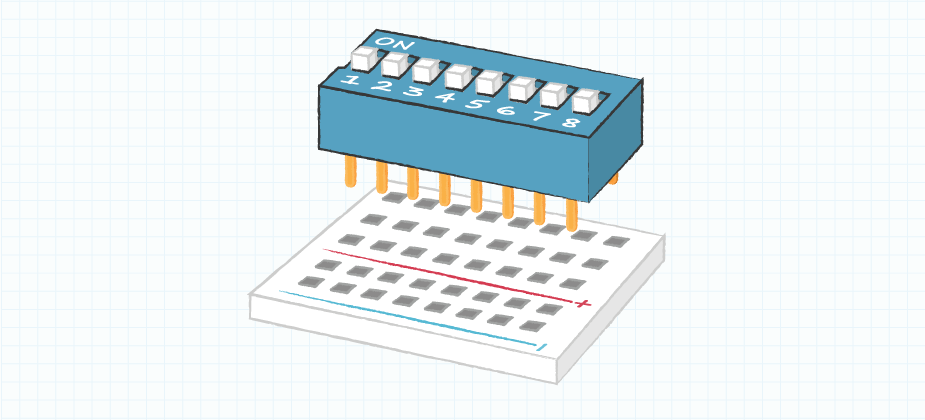

What Are DIP Switches?

DIP (Dual In-line Package) switches switches are compact arrays of SPST switches integrated into a single housing, available in through hole or surface mount formats. Commonly found on breadboards or embedded in end products, they allow users to make configuration selections using low-voltage, low-current signals.

They’re ideal for applications where semi-permanent settings are needed, such as setting device IDs or configuration modes, without the risk of losing jumpers. DIP switches are available in piano, slide, or rotary forms, with rotary DIP switches discussed in the next section.

Common Applications:

- Transmitters and receivers

- Development boards for signal routing

- Industrial controls with selectable modes

Explore more in our DIP Switches blog or watch our DIP Switches video.

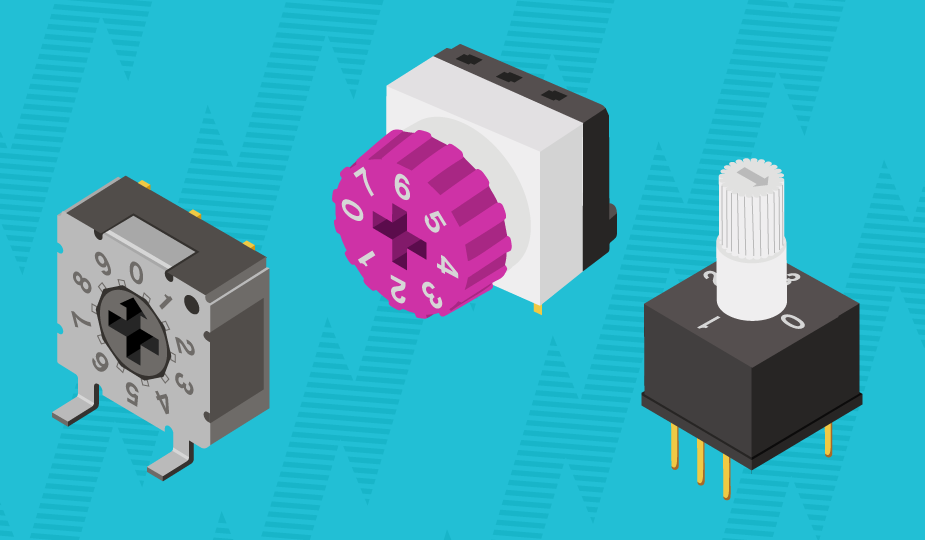

What Are Rotary DIP Switches?

Rotary DIP switches are a variant of the traditional DIP switch, using a rotating actuator to select between multiple discrete settings, typically 4 to 16 positions. They’re actuated via a small screwdriver or knob and offer outputs in binary-coded decimal (BCD) or hexadecimal formats.

While compact and easy to use, rotary DIP switches are typically limited to one output and not designed for continuous use. Their rotation life cycle is lower than that of many other switch types.

Key Benefits:

- Simple rotary selection

- Small PCB footprint

- Options for BCD or hex encoding

Explore more in our Rotary DIP Switches blog.

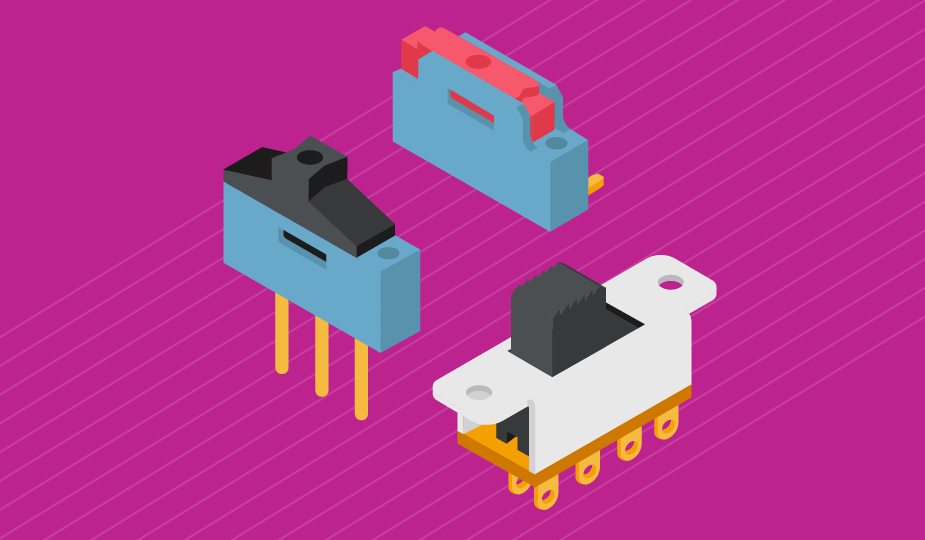

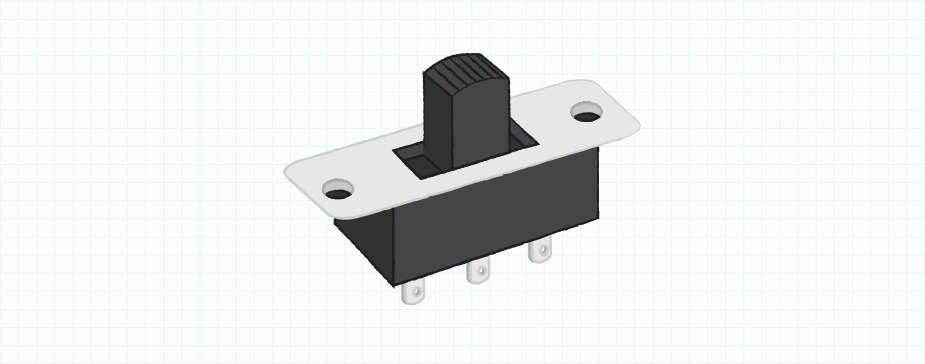

What Are Slide Switches?

Slide switches use a sliding actuator to open or close a circuit, often in an SPST configuration. They are commonly used as power switches in consumer devices and are rated for higher current and voltage than DIP switches.

Available in through hole and surface mount options, slide switches provide straightforward actuation but may present challenges when multiple throws are involved, as precise control becomes more difficult.

Common Use Cases:

- Consumer electronics

- Small power circuits

- Embedded control panels

Learn more in our Slide Switches blog.

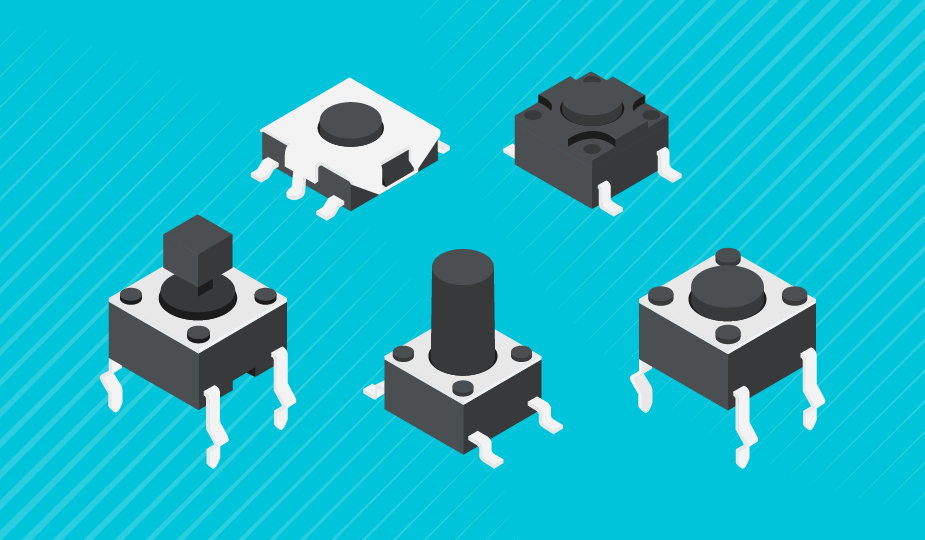

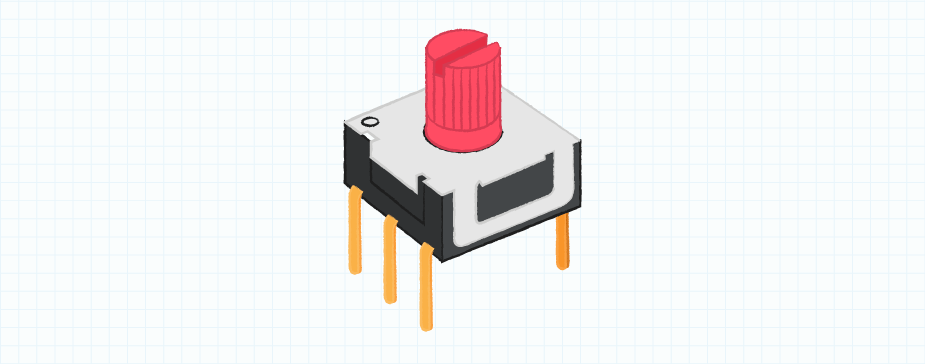

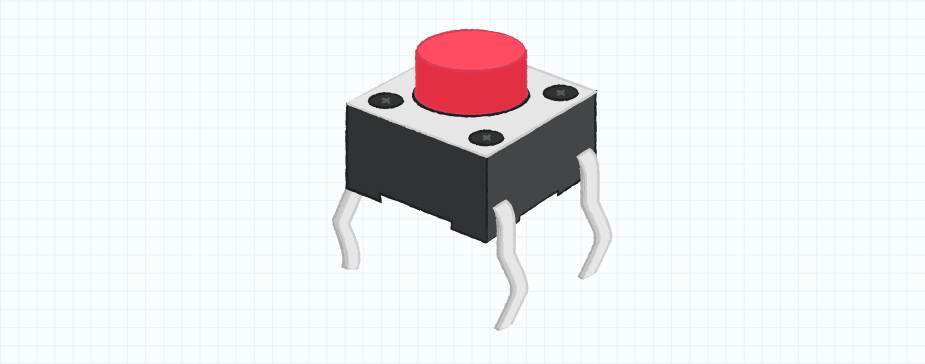

What Are Tactile Switches?

Tactile switches are small, momentary push button switches that deliver physical and audible feedback when pressed. Though limited to low voltage and current, they are engineered for high durability, with actuation life cycles ranging into the millions.

Tactile switches can be sealed for high ingress protection and are widely used in both consumer and industrial interfaces.

Notable Features:

- Click feedback for user confirmation

- Surface, through-hole, or edge mounting

- Long lifespan and compact design

Common Applications:

- Game controllers and remotes

- Automotive interfaces

- Medical or industrial user interfaces

Read more in our Tactile Switches blog.

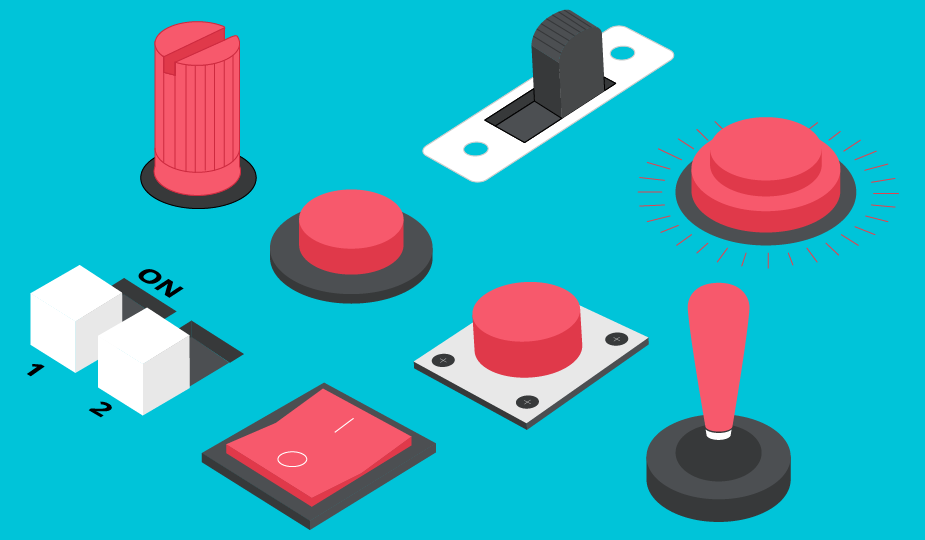

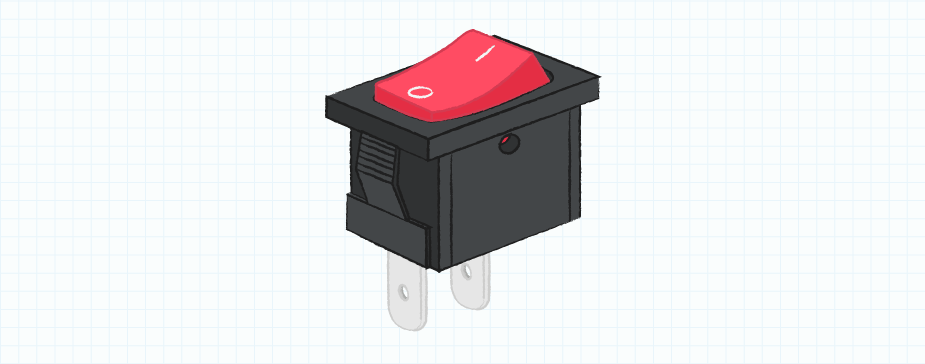

What Are Rocker Switches?

Rocker switches operate via a central pivot point, typically toggling between ON and OFF states. They are well-suited for mains voltage and high-current applications and can be momentary or maintained.

Often panel-mounted, rocker switches may include illumination (via LED or bulb) for state indication and can be sealed for outdoor or rugged environments.

Key Features:

- Intuitive actuation and visual status

- High voltage/current capability

- Optional illumination and sealing

Application Examples:

- Power switches in consumer electronics

- Industrial equipment

- Vehicle accessory control

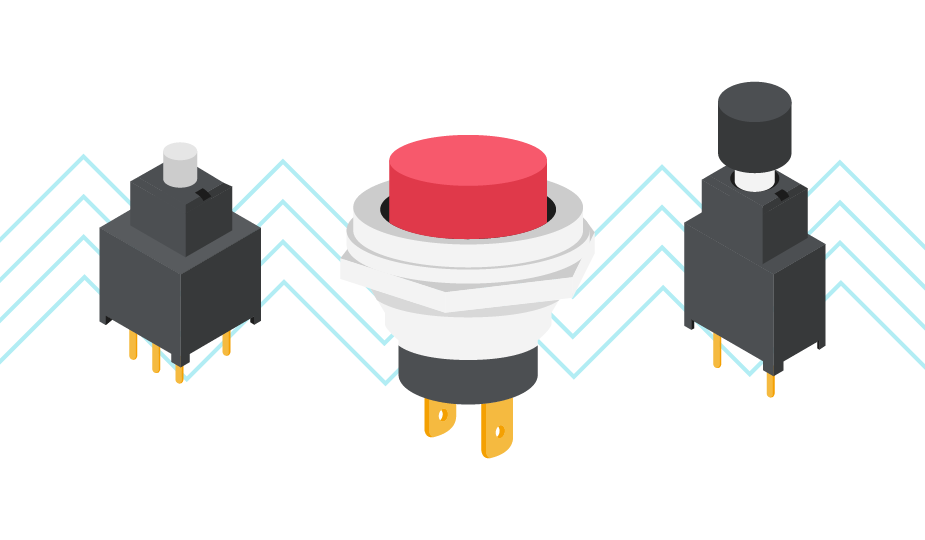

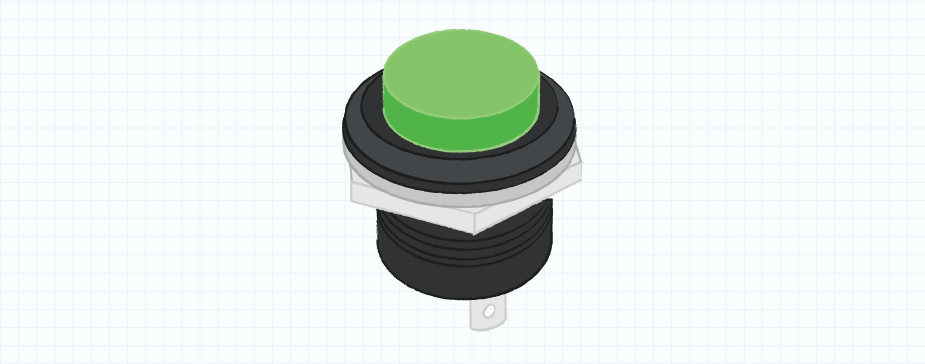

What Are Push Button Switches?

Push button switches are actuated by pressing a button inward, unlike the lateral or rotational movements of most other switch types. They are typically momentary and can be illuminated for visibility or status indication.

Available in a range of sizes and mounting options, push button switches are suitable for both low-power signaling and higher-power actuation. Ruggedized, vandal-resistant models are common in public or harsh environments.

Popular Use Cases:

- Elevators and kiosks

- Networking and telecom gear

- Audio or instrument panels

Learn more in our Push Button Switches blog.

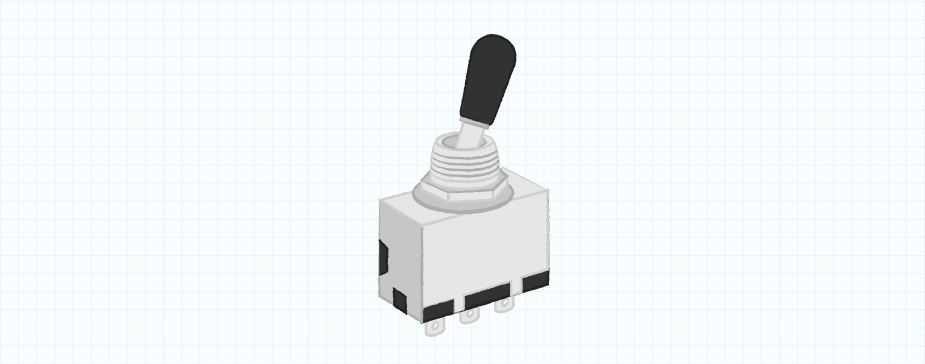

What Are Toggle Switches?

Toggle switches feature a protruding lever that flips between positions, offering strong tactile and visual feedback. They’re ideal for gloved operation or environments where precision actuation is limited.

With a wide range of poles and throws, toggle switches can support complex circuit requirements. While not usually momentary, some models allow this behavior.

Advantages:

- Easy to operate in industrial conditions

- Available in high-reliability formats

- Often panel-mounted for accessibility

Application Examples:

- Aviation and control instrumentation

- Medical devices

- Harsh or gloved-user environments

Comparing Switch Options

There are an extraordinarily large array of switches and those discussed here are only a small subset of possibilities. However, this small subset is sufficient to cover many applications and their different strengths and weaknesses allow designers to find the ideal solution for their project.

For the switches discussed, below is a summary of their prominent features and typical configurations. There are exceptions to nearly all these generalizations, but this provides a rough idea of their capabilities:

| DIP | Rotary | Slide | Tactile | Rocker | Push Button | Toggle | |

|---|---|---|---|---|---|---|---|

| Poles/Throws | Multiple | Multiple | Single | Single | Single | Single | Single |

| Cost | Low | Low | Medium | Low | Medium | High | High |

| Longevity | Low | Low | Medium | High | Medium | Medium | Medium |

| Current/Voltage Ratings | Low | Low | Medium | Low | Medium | Medium | Medium |

| Mounting Options | PCB | PCB | PCB/Panel | PCB | PCB/Panel | PCB/Panel | Panel |

Key Takeaways

- Switches are essential components in nearly all electronic devices, with vast diversity in size, actuation method, and interface style.

- Mechanical switches remain dominant in the market despite growing popularity of electronic switch technologies like BJTs, MOSFETs, and IGBTs.

- Poles and throws are fundamental concepts:

- Poles indicate how many circuits a switch can control.

- Throws indicate how many output paths are available per pole.

- Common switch configurations include SPST, SPDT, DPST, and DPDT, with many variations based on the number of poles and throws.

- Key features to consider when selecting a switch include:

- Size (ultra-compact to industrial scale)

- Default state (momentary vs. maintained)

- Number of positions

- Mounting options (through hole, surface mount, panel mount, DIN rail)

- Actuation method (manual vs. electronic; tool vs. finger actuation)

- Voltage and current ratings

- Environmental protection (IP ratings, vibration resistance, vandal-proofing)

- Popular types of mechanical switches and their typical applications:

- DIP switches – Compact SPST arrays for semi-permanent settings in embedded and industrial systems

- Rotary DIP switches – Small footprint selectors with BCD or hex outputs

- Slide switches – ON/OFF control in compact devices and consumer electronics

- Tactile switches – Momentary switches with high cycle life, ideal for user interfaces

- Rocker switches – High-current switches with intuitive operation and illumination

- Push button switches – Rugged, user-friendly switches for signaling and actuation

- Toggle switches – Lever-actuated, glove-friendly switches for industrial and critical systems

- Switch selection depends on both function and form, making aesthetics and interface style just as important as electrical and mechanical specs in many applications.