Why Multi-Turn Encoders Matter—and How to Use Them

What is a Multi-Turn Encoder?

Multi-turn encoders are a type of rotary encoder that not only track the position of a rotating shaft over a single revolution from 0° to 360° but also track the number of full rotations. Whereas a single-turn encoder repeats its output with every rotation, a multi-turn encoder tracks the full rotations as well as the absolute position within a current rotation.

In many motion systems, knowing the shaft angle within a single 360° rotation is only a part of the picture. To truly track position over time, you often need to know how many times the shaft has turned, especially when that rotation is linked to linear motion, gearing, or larger system movement. That is where multi-turn encoders come into play.

Why Tracking More Than One Turn Matters

If your encoder only gives you 0° to 360°, you might think, “I’ll just track turns in software.” In theory, this works: you monitor when the position rolls over from 359° to 0°, or vice versa, and increment or decrement a counter. In practice, this gets messy fast.

- Missed samples, power glitches, or brief communication losses can throw off your turn count.

- Noise and vibration might cause spurious position readings, leading to false turn detection.

- Rapid reversals near the 0°/360° boundary can confuse rollover logic and introduce cumulative errors.

Manually tracking turns in software often requires extensive filtering and tuning to get right—and even then, it is easy to lose count.

Multi-turn absolute encoders solve this problem at the hardware level. They maintain an internal revolution counter that updates alongside the shaft angle, giving you a complete picture of position with no guesswork.

Real-World Scenarios That Require Multi-Turn Encoders

Here are a few common examples where single-turn feedback just isn’t enough, and multi-turn encoders are needed:

- Gear or belt-reduced drives: If a motor turns 10 times for every output shaft rotation, you need to track those 10 turns—not just the final angle.

- Ballscrews and leadscrews: Each rotation translates to a fixed linear distance. Losing track of turns means losing track of position.

- Rack and pinion systems: The rotary input drives continuous linear travel; knowing how far you've moved means counting full shaft rotations.

- Rotary axes in robotics or automation: For rotating platforms, joints, or turrets, knowing cumulative rotation is critical for motion control and collision avoidance.

If your system moves through more than 360°, a multi-turn encoder can reduce software complexity and increase reliability.

How Do Multi-Turn Encoders Work?

Multi-turn encoders combine two critical capabilities: fine angle resolution within a single rotation, and a reliable count of full shaft revolutions.

Angle sensing is typically handled using technologies like capacitive, magnetic, or optical detection, allowing precise determination of the shaft's position within 0° to 360°.

To track the number of turns, multi-turn encoders include an internal counter that increments or decrements each time the shaft completes a full rotation. This counter is synchronized with the angle reading to deliver an absolute multi-turn position value.

Depending on the encoder type, turn counting may be handled mechanically (via gears), magnetically (via Wiegand wire pulse energy), or digitally (requiring constant power). Systems using the latter approach must ensure power continuity to preserve the turn count, often through software strategies or a small battery backup.

What Happens to Multi-Turn Encoders at Startup?

To work around power-up resets for multi-turn encoders, common strategies include:

- Use a Home or Limit Switch: On power-up, the system moves to a known mechanical reference point and resets position from there.

- Store the Last Known Value: If your system includes a host controller or external memory, it can store the last known angle and turn count. After restart, you reapply that position—as long as the shaft has not moved.

- Lock the Shaft at Startup: For planned shutdowns or ultra-low power standby modes, you can physically lock the shaft in place and reload the saved encoder value on startup. Since the encoder angle and turn count match what was previously stored, the position is restored—no movement, no error. This approach is especially useful in battery-powered systems or installations where motion is disabled during idle states.

- Design for Acceptable Loss of Turns: In some cases, absolute multi-turn position is not critical across power cycles. If your system reinitializes safely at startup—or recalibrates based on external sensors—you may be able to tolerate the reset

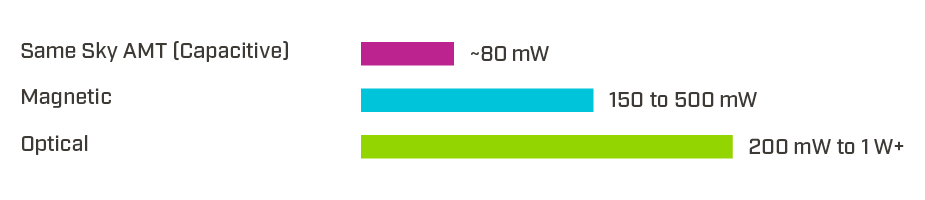

Same Sky’s capacitive AMT encoders typically consume just ~80 mW, making them an excellent fit for low-power applications. In comparison:

- Magnetic encoders commonly draw between 150 mW to 500 mW.

- Optical encoders often consume 200 mW to over 1 W, especially in high-resolution or light-source-based designs.

This makes capacitive encoders especially attractive in embedded, battery-operated, or power-conscious systems where every milliwatt counts. For an in-depth comparison of capacitive, optical, and magnetic encoders, check out our Comparing Encoder Technologies blog.

Multi-Turn Encoder Integration Considerations

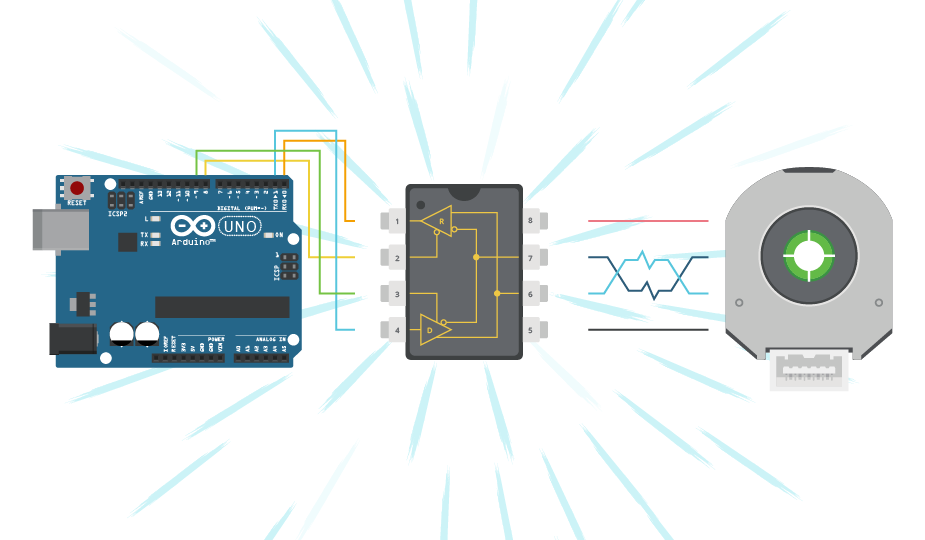

Multi-turn encoders are available with interfaces like SPI and RS-485. While the exact communication protocol varies, most make it simple to read both angular position and turn count using a small number of bytes or commands. The commands for Same Sky’s AMT encoders are documented in their respective datasheets. We also have sample code tutorials available to show how to access the multi-turn functionality from an Arduino.

| Same Sky AMT Encoder | Protocol | Datasheet | Sample Code |

|---|---|---|---|

| AMT21 Series | RS-485 | AMT21 Datasheet | AMT21 RS-485 Sample Code |

| AMT24 Series | RS-485 | AMT24 Datasheet | AMT24 RS-485 Sample Code |

| AMT22 Series | SPI | AMT22 Datasheet | AMT22 SPI Sample Code |

| AMT25 Series | SPI | AMT25 Datasheet | See AMT22 Sample Code |

Integration is straightforward, but designing the system around the encoder’s startup behavior is key.

When to Choose a Multi-Turn Encoder

You will benefit from a multi-turn encoder if your application:

- Requires position tracking beyond one rotation

- Converts rotary motion to linear travel

- Uses high gear ratios

- Needs absolute position with minimal software filtering

- Benefits from simpler, more robust startup logic

Same Sky’s AMT absolute encoders include compact multi-turn options with SPI and RS-485 interfaces. Designed for embedded systems, they offer low power draw, modular mounting, and simple digital communication—ideal for motion systems that need absolute tracking across multiple turns (just remember to manage power-up resets properly). Learn more about absolute encoders in our blog, When is an Absolute Encoder Right for Your Design?

Using Battery Backup to Preserve Turn Count

If your application cannot tolerate losing the revolution counter during a power cycle, a battery backup is one of the most reliable solutions. Rather than relying on recalibration or external sensors, this approach simply keeps the encoder powered through a short or extended loss of system power. Because Same Sky’s AMT encoders consume just ~80 mW, they are exceptionally well-suited for battery-backed operation.

Conclusion

Multi-turn encoders simplify motion control by tracking full rotations internally, reducing software overhead, and ensuring position data stays accurate across a wide range of mechanical systems. This makes them a valuable tool for engineers designing reliable, scalable motion systems. Same Sky’s AMT absolute multi-turn encoders support motor shaft sizes from 2 mm up to 5/8 inch (15.875 mm), which gives designers additional flexibility for their position sensing needs.

Key Takeaways

- Multi-turn encoders provide absolute position feedback across multiple shaft rotations, unlike single-turn encoders that reset every 360°.

- Tracking turns in software is error-prone due to missed samples, power glitches, and noise. Hardware-based multi-turn encoders solve this reliably.

- Applications that demand multi-turn encoders can include gear-reduced drives, ballscrews, rack and pinion systems, and rotary axes in automation or robotics.

- Effective startup solutions for retaining position include homing switches, saved position recall, shaft locking, or designing for safe reinitialization.

- Multi-turn encoders may use mechanical, magnetic, or digital methods to count full rotations.

- Digital turn counting requires strategies to preserve state across power loss, such as battery backup or startup recalibration.

- Battery backup is a reliable option when turn count persistence is critical during power interruptions.

- Capacitive multi-turn encoders like Same Sky’s AMT series offer ultra-low power consumption (~80 mW), making them ideal for embedded and battery-powered designs.

- Choose a multi-turn encoder when your system needs to track motion beyond one revolution, convert rotary to linear motion, or might benefit from simplified, robust position control.