Fan Bearing Types – Weighing the Pros and Cons

For many electronic systems, fans are an important component designed to keep the system within recommended temperatures, ensuring that the electronics work optimally and last their full operational lifetime. There have been attempts to find alternative thermal management techniques, but none have proven to be as efficient and cost effective as the fan.

Shop Same Sky's full range of ac fans and dc fans or explore our other fan blog topics:

- Axial Fans vs. Centrifugal Fans – What’s the Difference?

- Cooling Fans: Monitoring, Control, and Protection Enhance System Performance

- Understanding Airflow Fundamentals for Proper Dc Fan Selection

- Thermal Management with Fans – There's More to Consider Than You Might Think

- Or watch our Fan Bearing Types video

The fan works by using a rotor that spins on a bearing to displace air. The reliable operation of the bearing is key to the fan design, as the fan can rotate thousands of times per minute and be required to have a lifespan of many years. This process puts the bearing under an enormous amount of stress, so it is essential that it is up to the task.

There are two bearing designs that are widely used, the sleeve bearing and ball bearing, and each has its pros and cons.

Sleeve Bearing Fans

Sleeve bearing fan designs are inexpensive, rugged and simple, which has led to their widespread use in many applications. The rugged design ensures that they are able to work in many harsh environments and their simplicity means that they are less prone to malfunction. Another benefit to sleeve bearing fan designs is that they tend to create less noise while operating, allowing them to be used extensively in quiet areas like offices.

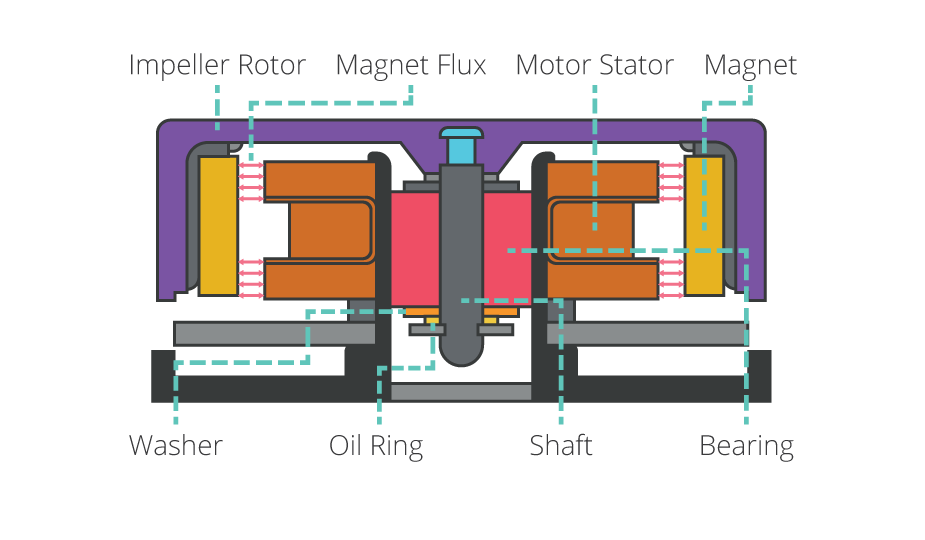

The central shaft of a sleeve bearing fan is encased in a sleeve-like structure, with oil for lubrication to ease rotation. The sleeve offers protection to the shaft and ensures the rotor is kept in the right position, preserving the gap between the rotor and stator.

There can be a balancing act to get the correct gap size between the shaft and the sleeve. Too little space results in an increase in friction, which makes the fan harder to start and draws more power. If the gap is too big, then the rotor can wobble. The second drawback to sleeve construction is that the sleeve is the only physical medium holding the rotor in place, and over time the shaft will erode the bearing bore. This phenomenon is worse if the rotor always rotates in the same direction, which will eventually lead to the bore taking-on an oval shape, resulting in noisier operation and a shortened operational lifetime. If the fan is moved around or re-orientated, the bearing will be eroded in different places and become uneven – making wobble and noise even worse. In addition, the sleeve-type construction requires oil rings and Mylar washers to prevent the lubricant from leaking, which causes more friction to the shaft and stops gases from escaping. Trapped gas solidifies into nitride particles that impede movement and can shorten the fan’s operational life.

Sleeve bearing fans can be found in many designs, particularly in those that operate in normal temperatures and on static equipment. Applications, such as computer and office equipment, HVAC appliances and industrial cabinets make extensive use of sleeve bearing fan designs.

Ball Bearing Fans

Ball bearing fan designs are intended to combat some of the drawbacks found in sleeve-bearing fans. In general, they are less prone to wear and tear and can operate in any orientation and at higher temperatures. However, ball bearing fans are more complex and expensive than sleeve-bearing designs, as well as being less rugged. As a result, impacts can greatly affect the overall performance of a ball bearing fan. They also tend to create more noise when in use, which can restrict the areas they can be deployed.

Ball bearing fan designs use a ring of balls around the shaft to solve uneven wear and rotor wobble problems. Most fan motor designs have two bearings, one in front of the other, and these bearings are usually separated by springs. The bearings offer reduced friction compared to sleeve designs and the springs can assist with any tilt in the fan that the rotor’s weight may induce. If the springs are placed the whole way around the shaft, the device can be operated at any angle without wear or friction, giving a more reliable design.

Ball bearing fans can also be found in high density computer applications and datacenters, where performance, temperature and MTBF are more important factors than noise. They are also widely used in industrial applications for cooling electronics systems or as blowers for industrial drying applications.

omniCOOL™ System Fan Bearing

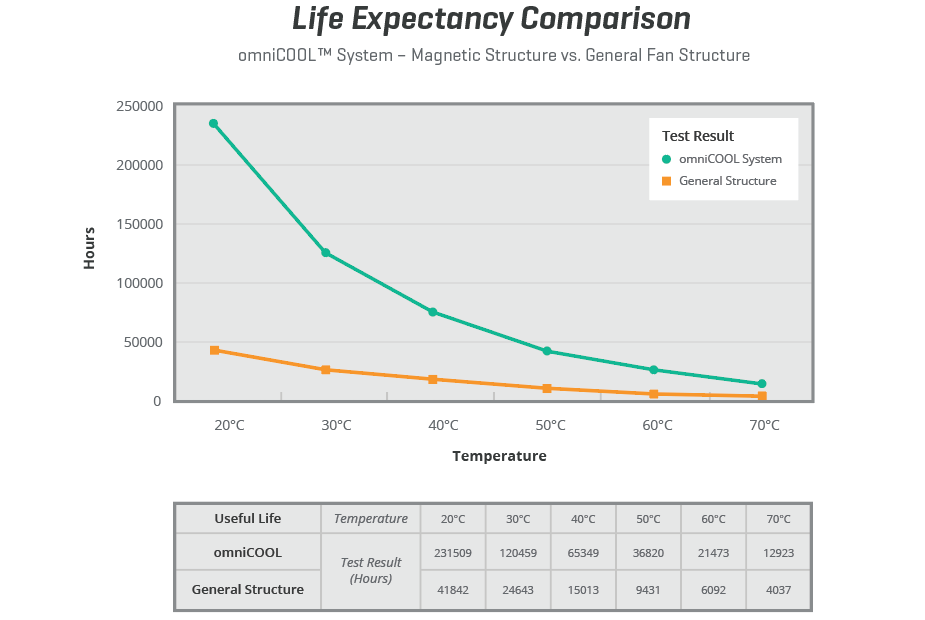

Ball and sleeve bearing designs are not the only two options available. There is an alternate option introduced by Same Sky called the omniCOOL system™, found in our line of advanced sleeve bearing fans. Utilizing either magnetic rotor-balancing, commonly referred to as the magnetic structure, or an enhanced bearing, the omniCOOL system technologies work to provide extended fan life and improved performance.

Magnetic Structure

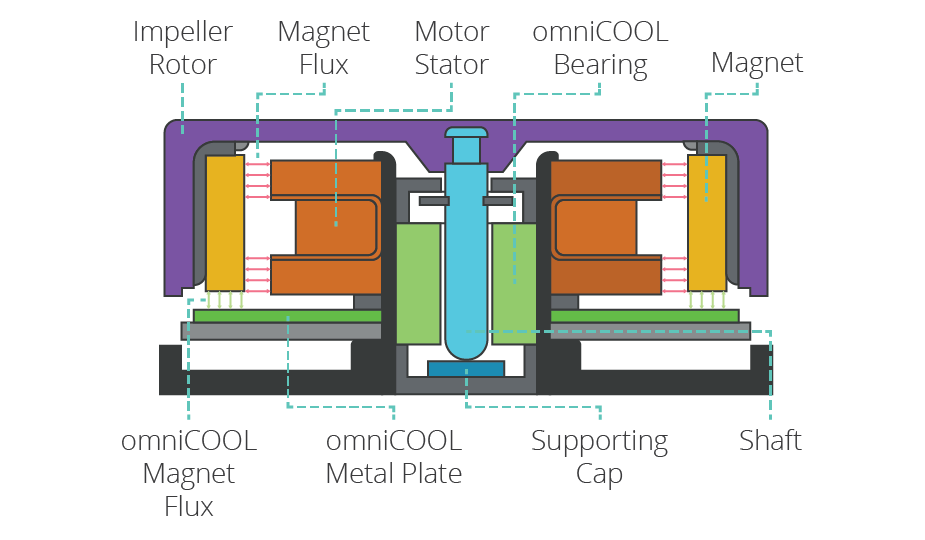

Dc fans with the omniCOOL system that utilize the magnetic structure design include a “-V” suffix on respective part numbers. The omniCOOL system’s magnetic structure effectively makes the rotor work like a spinning top – but one that never falls over and can operate at any angle. The magnetic structure sits in front of the rotor and because its flux is parallel to the direction of the rotor shaft, uniformly attracts the entire rotor, at whatever angle the fan unit is being held.

The shaft tip is held in place by a supporting cap at the very front of the bearing bore. This forms the point around which the rotor can rotate, like the point on a spinning top. Thanks to the magnetic structure, the shaft and bearing sleeve no longer bear the weight of the rotor, which is instead suspended in the air. Additionally, the magnetic field works to lower the center of gravity by pulling the shaft downward, which minimizes the tilt and wobble issues that exist with traditional sleeve bearings, thereby enabling a fan with the omniCOOL system’s magnetic structure to be used at any angle. It also dramatically reduces the friction between the shaft and the inside of the bearing. This leads to a longer operating life than a traditional sleeve bearing.

In addition, because the magnetic structure prevents the shaft from physically rubbing against the inside of the bearing, the need for lubricant is reduced. The omniCOOL system takes advantage of this by removing the oil rings and Mylar washers that would be required in traditional sleeve bearings. This has several advantages. It removes a big source of friction, which reduces noise and makes it easier to physically start the motor. It also creates a clear space at either end of the shaft, enabling the gas generated by the rotational friction to escape, rather than solidifying and clogging the bearing.

Enhanced Bearing

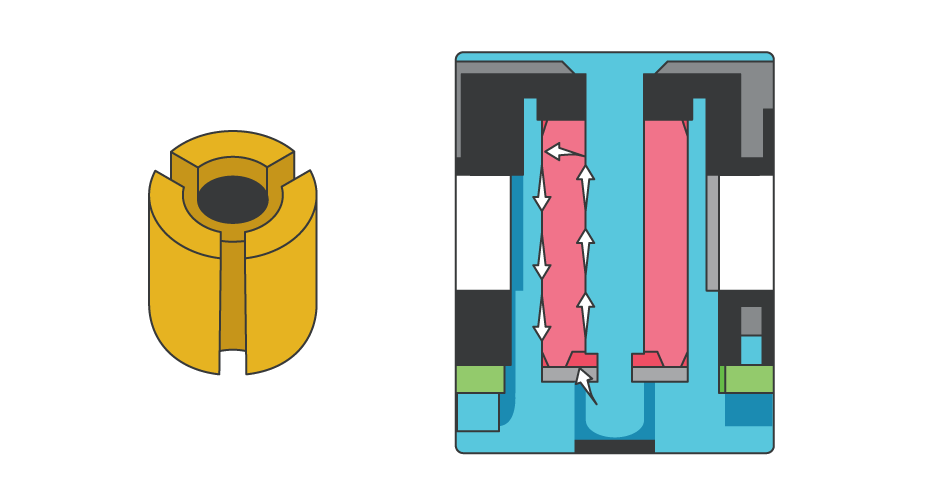

Dc fans with the omniCOOL system that utilize the enhanced bearing design include a “-C” or “-CF” suffix on respective part numbers. The omniCOOL system’s enhanced bearing design incorporates specialized grooves on the outside of the bearing that assist with circulation of lubricant around the shaft. As the fan begins to rotate, heat generated by the rotating shaft naturally draws lubricant up between the bearing and shaft. The specialized grooves on the outside of the bearing then promote the flow of lubricant back downstream, thus forming an improved lubrication cycle.

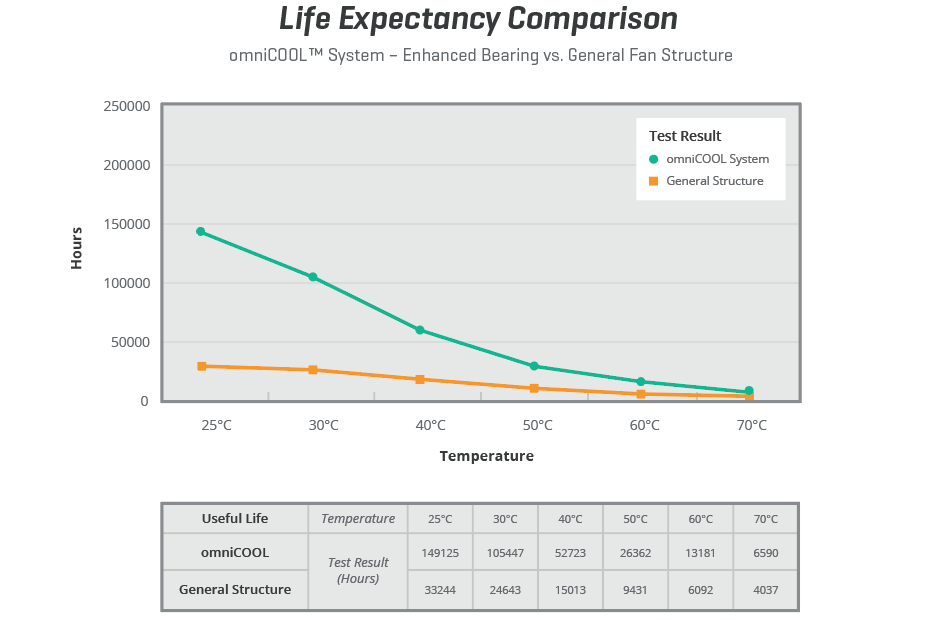

The improved circulation of the omniCOOL system’s enhance bearing also works to reduce friction and build-up of lubricant, leading to more efficient operation, less noise, and longer life expectancy compared to traditional designs.

While the magnetic structure of -V series fans and the enhanced bearing of -C or -CF series fans both minimize the cost-performance tradeoff of traditional sleeve and balling bearing designs, the -V series does offer a longer life expectancy than the -C or -CF series. On the other hand, the enhanced bearing of -C or -CF series fans are more economical.

Bridging the Gap in Traditional Fan Designs

The omniCOOL system alleviates the negatives of both ball bearing and sleeve bearing fan designs, resulting in a robust fan that is quiet and cost-efficient with a longer operational life. By negating the drawbacks from the other two types of fan construction, the omniCOOL system can be deployed to replace either type of fan. Instead of being forced into a compromise, designers can have access to a fan construction that delivers the best of both worlds.