Understanding Connector Safety Requirements

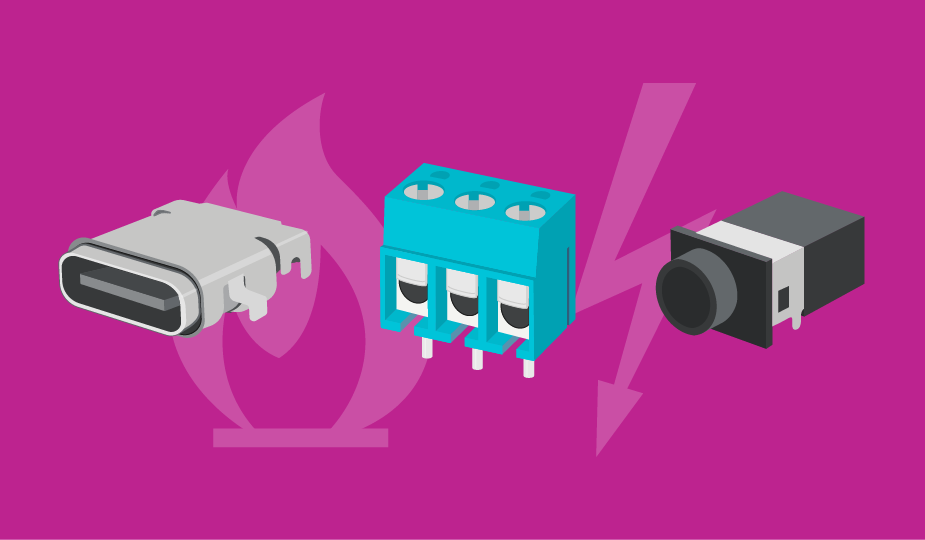

In just about any electrical device, you will find connectors utilized for signal, power, data, or audio transfer. They can be used for low or high voltage designs, for commercial or industrial applications, and everything in between. With all the variations, what is actually required for safety certification? Why do some connectors have safety certification, and why do others not?

Low Voltage Connector Safety Misconceptions

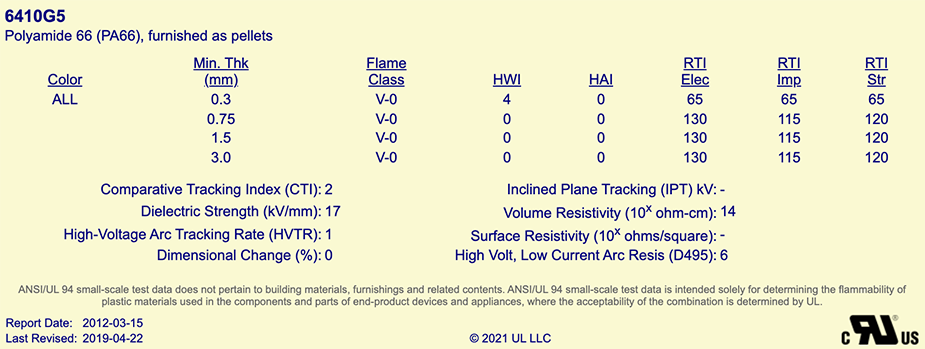

In low voltage, low power connectors, safety certification is not typically needed on the connector itself. When a product goes into safety certification, safety testing is done on the entire product design, which also takes into account the individual components including the connectors. Although these types of connectors do not require safety certification, they are often made from plastic material that meets a flammability rating, such as UL94, which is a safety standard by UL that classifies plastics by how they burn in various orientations and thicknesses. Below are common flame classes from the lowest to most flame retardant.

- HB: slow burning on a horizontal specimen; burning rate < 76 mm/min for thickness < 3 mm or burning stops before 100 mm.

- V-2: burning stops within 30 seconds on a vertical specimen; drips of flaming particles are allowed.

- V-1: burning stops within 30 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed.

- V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed.

- 5VB: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may develop a hole.

- 5VA: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may not develop a hole.

However, just because a connector utilizes a material with a certain flammability rating, does not mean that the part is a UL certified component. The UL flammability certificate, often referred to as the UL Yellow Card, can be provided upon request. The certificate details what specific flame class that the raw plastic meets.

High Voltage Connector Safety Risks

While low voltage connectors typically do not need or have safety certifications, high voltage connectors can require safety certification due to their higher safety risk such as electric shock, fire, and high temperature rises, so more precautions are needed. These connectors would typically be terminal blocks or other high voltage connectors often used in industrial applications. In either case, one needs to refer to the actual certification requirements of the end equipment to see if individual connector certification is needed.

Conclusion

By having a basic understanding of the safeties required for interconnect components, engineers can select parts with confidence and avoid costly safety certification issues and delays. The connectors that Same Sky offers are made from materials with a UL94 rating, most meeting UL94V-0. Our high voltage rated terminal blocks are UL recognized components.