The Importance of Power Relays in Reliable and Efficient HVAC Design

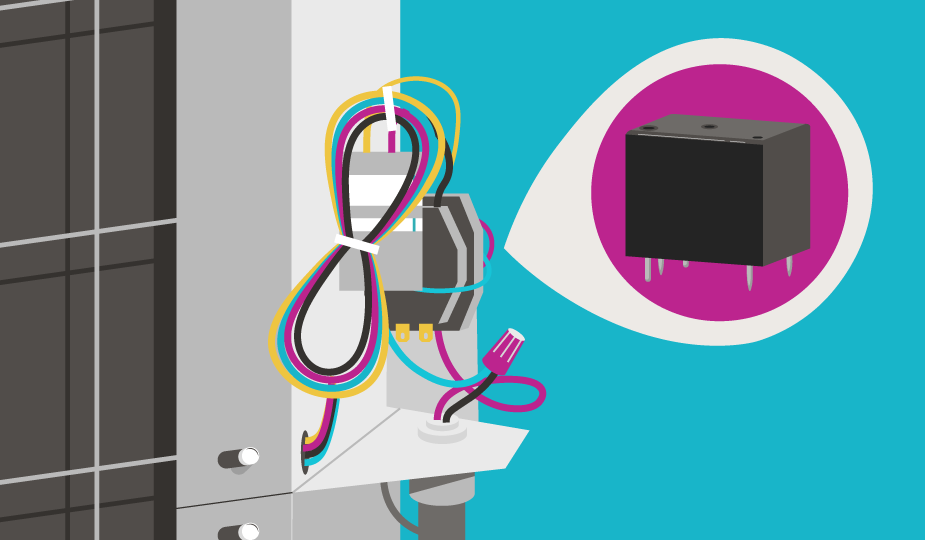

Power relays are the quiet yet important intermediaries that let a thermostat or controller move real power. Each time a compressor starts, a fan turns, a heat strip turns on, or a heat pump reverses flow, a relay needs to make a clean, repeatable, and safe transition between states. Because HVAC systems involve high inrush currents, frequent cycling, wide ambient temperature swings, and large amounts of moisture, the choice and application of relays have an outsized impact on comfort, efficiency, and long-term reliability. With the rising deployment of cooling and heat pumps, driven by summers, electrification, and retrofit incentives, there is more equipment and tighter reliability expectations. In addition to reliability, efficiency targets, such as SEER, HSPF, or other local energy codes, push designers to limit standby draw, reduce losses at the board level, and manage contact wear so systems hold their efficiency over time.

It is important to discuss regional variation from the beginning. HVAC designs are sold into many markets that differ in mains voltages and frequency, control conventions, environmental ratings, and regulatory frameworks. Rather than break down the rules country by country, we will speak broadly and flag the most common variations that influence relay selection and integration. If your product ships to multiple regions, align your relay choices and PCB spacings with the most demanding or stringent requirements so that you don’t need a redesign late in the design process. To help get you started, shop Same Sky’s wide selection of power relays as well as signal relays. Our blogs on relays and power relays also provide additional support.

Introduction to Relays for HVAC Systems

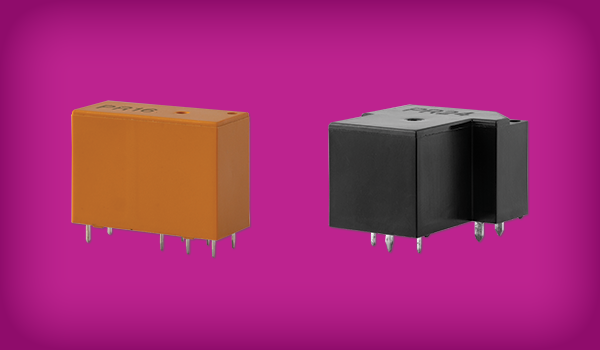

As mentioned, relays serve as the bridge between low-power control signals and high-power electrical loads. Relays are typically either panel-mounted contactors for large loads such as compressors, or PCB-mounted relays that switch indoor fans, heaters, and smaller motors. Both the panel-mounted and PCB-mounted relays must operate reliably through millions of cycles, often in harsh environments.

Control voltages vary depending on design and region. In many North American systems, a 24-volt AC control loop derived from a small transformer has been the standard for many years. Modern inverter-driven systems, however, often rely on low-voltage DC logic, such as 5 or 12 volts, to energize relay coils directly from the control board. Other regions may have completely different conventions. This means engineers must carefully confirm coil ratings, pickup and dropout voltages, and tolerance under brownout conditions to ensure consistent performance. Relays may look like simple components, but the choice of coil type, contact material, and form factor directly impacts the overall efficiency, serviceability, and reliability over the lifetime of the HVAC unit.

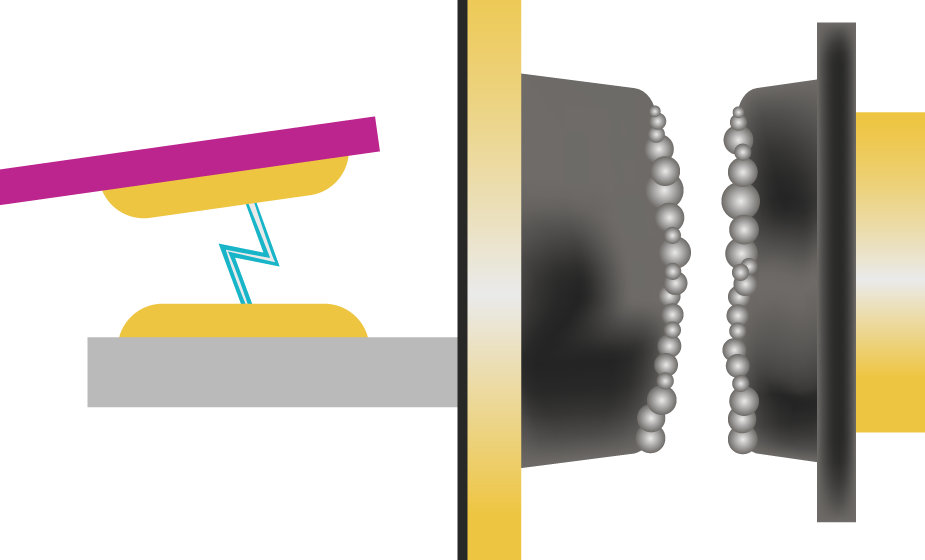

One of the greatest challenges relays face in HVAC is high inrush currents. Motors, particularly compressors, condenser fan motors, and indoor blower motors, can draw upwards of five to eight times their rated full-load current the instant they start. This inrush current places enormous stress on relay contacts. During closure, the contacts are forced to carry a surge of current while an electric arc forms across the gap when the contacts are close but not fully touching. The arc can erode contact surfaces, increase resistance, and generate heat that shortens the relay’s life. If the contacts bounce even slightly, the arc lengthens and intensifies, further accelerating wear. Because of this, contact materials such as silver tin oxide are favored because they resist welding and erosion under inductive loads. Same Sky offers a variety of power relays at different switching voltages with silver tin oxide for HVAC and other applications that expect these unfavorable conditions.

In fixed-speed compressor systems, this inrush current occurs at every start, making durability under these conditions a primary design requirement. Inverter-driven compressors present their own challenges. Because they ramp up gradually, the inrush current is much lower, reducing stress on the main contactor. However, the demands shift toward relays controlling secondary functions, such as reversing valves, heaters, pumps, and other items that cycle frequently. Even smaller relays must be chosen carefully as small inductive loads still generate damaging voltage spikes without proper suppression networks like RC snubbers or varistors.

Where Are Relays Used Inside HVAC Systems?

Beyond the compressor contactor, relays appear throughout HVAC designs. Condenser fan motors and indoor blower motors are often switched through relays that handle both the mechanical load of frequent starts and the electrical stress of inductive currents. Although these motors are smaller than the compressor, their repeated cycling over the life of the unit makes contact wear and coil endurance important design considerations.

Heat pumps add another critical application – the reversing-valve solenoid. This comparatively small, yet essential load determines the direction of refrigerant flow, switching the system from heating to cooling and back. The relay that drives it must operate with reliable timing and clean transitions to avoid harmful pressure spikes. In addition, HVAC systems frequently rely on relays to control resistive heating elements, including crankcase heaters that prevent refrigerant migration and auxiliary heat strips that provide supplemental heating in very cold weather. These strip heaters can be staged in increments of several kilowatts each, requiring relays capable of handling high continuous current without excessive temperature rise. Smaller, yet still important tasks, such as operating condensate pumps or humidifiers, also rely on relays, showing how central these devices are to HVAC systems.

Relay Design Considerations and Concerns for HVAC

Electrical performance is the first consideration when it comes to design. Relays must be rated not only for continuous current but also for the high current spikes common in motor-driven loads. In addition to the inrush current, if a mechanical block prevents the motor from turning, the current draw will increase significantly, known as the locked rotor amperage (LRA). While less common, these longer events can put significant strain on the wiring, electronics, and relays of the HVAC system and should be factored into the design. Finally, the break event, when contacts open, is often the harshest condition, and can lead to the arcing discussed earlier.

While electrical performance is paramount, environmental conditions cannot be ignored. HVAC equipment operates from rooftop heat in the summer to winter blizzards in exposed locations. Relays must perform reliably across ambient temperatures ranging from below -40°C to above 60°C, often with humidity, condensation, or airborne contaminants present. This makes insulation, sealing, and material selection key.

Control voltage conventions vary widely, even within the same market. While most North American units still use 24 Vac control loops, other designs employ low-voltage DC control, and some high-voltage systems drive relays directly from mains-level logic. Each approach has implications for coil design, pickup and dropout behavior, and efficiency. Reliability is another constant concern. HVAC relays must endure frequent cycling, with inductive loads accelerating both mechanical and electrical deterioration. Finally, regulatory requirements such as UL or IEC standards dictate minimum safety margins, creepage and clearance distances, and flammability ratings. Relay choice must be aligned with these frameworks to avoid late-stage compliance problems.

Air-Source Heat Pump Design Challenges

Air-source heat pumps present unique challenges that increase the demand on relays. A key function is switching the reversing valve to alternate between cooling and heating. Each state change must be coordinated with compressors and fans, making the timing more of a challenge. Auxiliary electric strip heaters are also common in heat pumps, turning on when outdoor conditions are too cold for the refrigerant cycle alone to provide comfort. Relays managing these heaters must handle large resistive loads that can draw tens of amps continuously.

The defrost cycle adds further complexity. In cold weather, the outdoor coil can ice over, and the system must temporarily reverse into cooling mode to melt the frost, requiring significantly more state changes. During this cycle, relays switch compressors, fans, and heaters in a precise sequence to maintain indoor comfort while ensuring outdoor frost is cleared. Cold weather also increases compressor start currents, placing higher stress on contacts if fixed-speed designs are used. To meet modern efficiency standards, many systems are moving toward low-power coil designs or latching relays on control boards to reduce standby consumption. However, designers and engineers must remember that while latching relays reduce the relay’s own coil power, they do not reduce the hold power required by the controlled devices, such as the reversing-valve solenoid.

Relay Selection Checklist for HVAC

While HVAC relay requirements are complex, a straightforward checklist can help guide the process.

- Review the load, including motor power, resistive heater loads, separate make/break ratings, and inrush or locked rotor amperage.

- Confirm voltage and frequency requirements, whether 120 Vac or 240 Vac, 24 Vac, DC, single- or three-phase. Whatever voltage and frequency are most common in your area, make sure you meet those needs.

- Evaluate expected ambient temperatures and enclosure conditions, and select insulation and sealing accordingly, not just for the relays but for all the electronic components.

- Verify compliance with regulatory requirements such as UL and IEC standards.

- Consider serviceability, including whether relays will be field-replaceable and how technicians will interact with them.

- Ensure that the coil type matches the mode of operation and that the coil power requirements are matched to what the control system can supply.

Conclusion

Relay selection is only one aspect of HVAC design, but it is a critical one. The choice of relays affects energy efficiency, compliance with regulatory standards, and the ease of servicing equipment in the field. With HVAC deployment increasing worldwide and efficiency standards becoming ever more stringent, designers must treat relays as more than an afterthought. Thoughtful selection ensures quiet, reliable, and efficient systems that can meet today’s climate demands while standing up to years of demanding service. Same Sky’s wide selection of different power relays provides an array of high-quality choices that thrive in this growing, yet demanding field.

Key Takeaways

- Power relays are critical to HVAC performance — they bridge low-power control signals and high-power loads like compressors, fans, and heaters.

- Reliability matters — relays must withstand high inrush currents, frequent cycling, and harsh environmental conditions.

- Efficiency standards drive relay design — choosing low-loss, durable relays helps maintain SEER, HSPF, and local energy code compliance.

- Regional differences affect selection — voltage, frequency, and regulatory frameworks vary, so design for the most demanding requirements.

- Material choice impacts durability — silver tin oxide contacts resist welding, arcing, and erosion in inductive loads.

- Heat pumps add complexity — relays manage reversing valves, auxiliary heaters, and defrost cycles, requiring precise timing and durability.

- Checklist approach helps engineers — reviewing load, control voltage, environment, compliance, and serviceability ensures long-term reliability.