The Critical Role of Rear Enclosures in Miniature Speakers

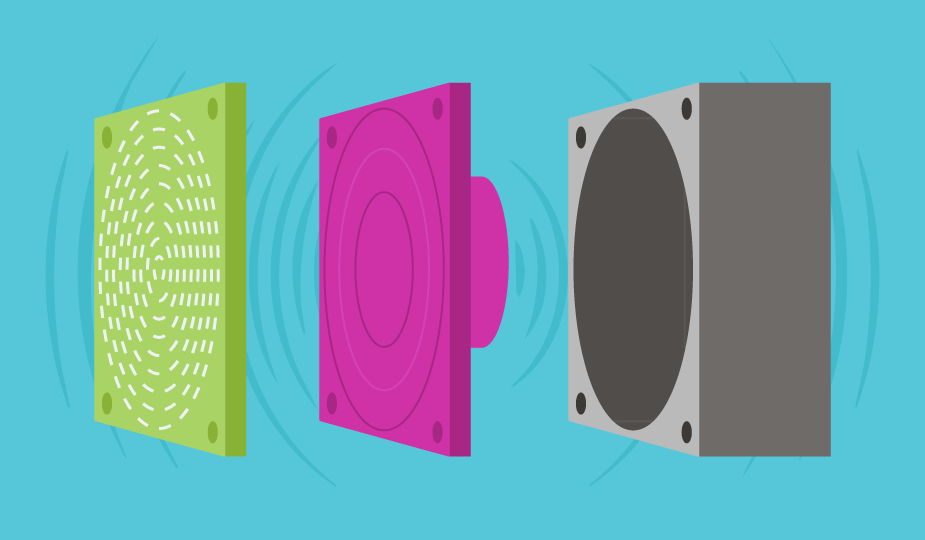

Speakers rely not only on their internal design but also on the environment they operate in. For mini and micro speakers, the rear enclosure is a critical part of the system, shaping both acoustic performance and long-term reliability. To see why, it helps to start with the core anatomy of a speaker.

How Do Speakers Work?

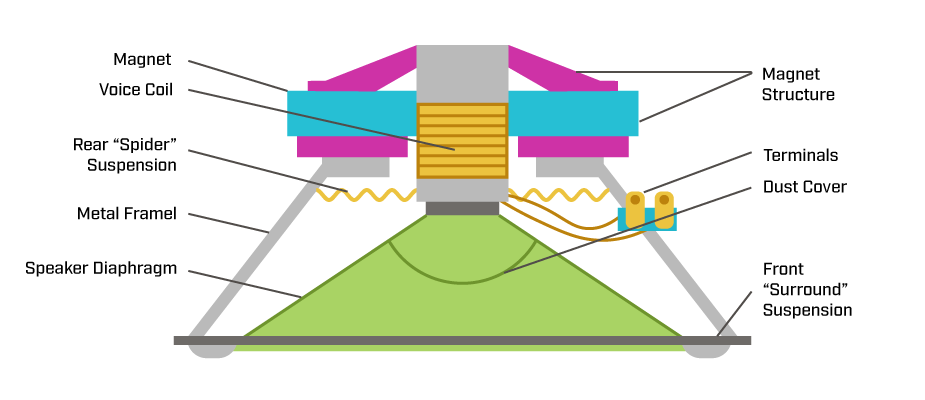

At their core, speakers all work the same way: a voice coil suspended in a magnetic field drives the diaphragm forward and backward, creating the air pressure waves we hear as sound.

Where they differ is in scale. Standard speakers benefit from larger diaphragms and sturdier suspensions, making them less sensitive to small changes in air pressure. In contrast, mini and micro speakers often use a thinner, more compliant suspension that responds strongly to their acoustic environment. This sensitivity makes enclosure design especially critical for small formats, but the same principles: managing back pressure, stabilizing diaphragm motion, and tuning frequency response, also apply to larger speakers when precision performance is required. To understand how this works in practice, let’s look at the role of the rear enclosure. For more information on speaker basics, check out our All You Need to Know About Speakers in Audio Design blog.

What is a Rear Speaker Enclosure?

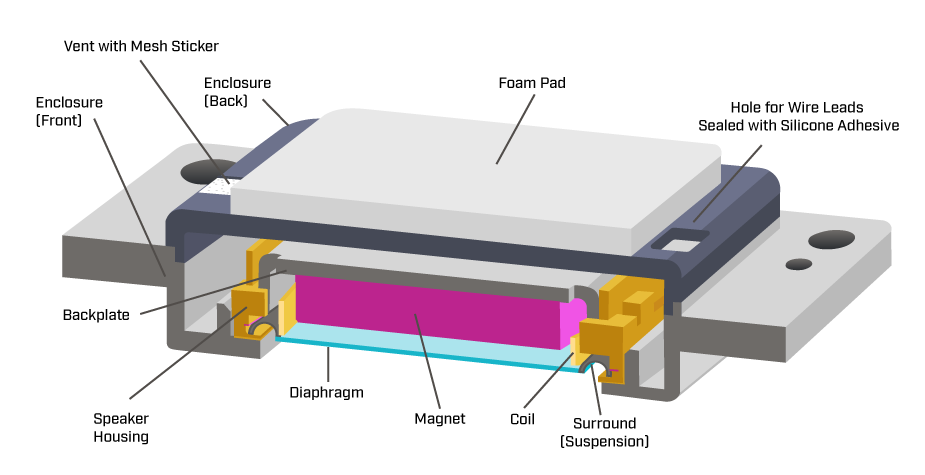

A rear enclosure is the cavity behind the speaker that contains and controls the air displaced during operation. In miniature speakers, this space plays a crucial role in both acoustic performance and mechanical function.

The enclosure provides back pressure that influences diaphragm movement, shaping frequency response and sound pressure level (SPL). While most miniature speakers can benefit from a rear enclosure, some designs depend on one to operate. In these cases, the rear enclosure is integral to mechanical stability, making it a vital part of the speaker system rather than just a housing.

Why Do Some Miniature Speakers Require Rear Enclosures?

Certain miniature speakers are engineered to rely on a rear enclosure for proper operation. In these designs, the enclosure provides essential back pressure that acts like a mechanical spring, controlling diaphragm movement and protecting internal components.

This approach has key advantages. By externalizing part of the suspension system to the enclosure, these speakers can be made thinner and more compact while still delivering strong performance. They often achieve higher efficiency for their size, can reach lower frequencies than comparable free-air designs, and allow designers to fine-tune acoustic response by adjusting enclosure volume.

Without the specified enclosure, however, the diaphragm can move excessively, placing stress on the surround. This overexcursion can cause stretching, deformation, or tearing, leading to premature speaker failure. Beyond mechanical risks, operating a speaker without its required enclosure degrades performance: lower SPL, reduced frequency response, and distorted audio output.

Because these failure modes are most common in compact designs with thin surrounds, it is critical to follow datasheet guidance and include the specified rear enclosure. Ignoring these requirements can result in costly product returns, warranty claims, and delays.

Why Do Many Speakers Benefit from Rear Enclosures?

Not every speaker is engineered to require a rear enclosure. Many mini and micro speakers, as well as standard speakers, are designed to operate in free air and will function without one. With that being said, integrating an enclosure can still provide clear advantages.

For miniature speakers, an added enclosure can boost low-frequency output, flatten the frequency response, and reduce distortion, helping small devices deliver sound that exceeds expectations. For standard-sized speakers, enclosures can be used to tune performance, suppress unwanted resonances, or optimize output within constrained housings.

Treating the enclosure as an active design element (matching volume to compliance, ensuring proper sealing, and evaluating sealed versus vented options) can improve efficiency and produce more balanced audio. Even when not strictly required, these improvements show why many speakers benefit from enclosure integration.

Designing With Rear Enclosures in Mind

When required, integrating a rear enclosure effectively is crucial to achieving the specified performance and reliability. Start by reviewing the speaker’s datasheet, especially noting any “conditions” listed with the SPL parameter. If a rear enclosure is required, the volume will be listed in cubic centimeters (cc). If no volume is mentioned, the speaker does not require one, but an enclosure may still be added to tune performance.

Enclosure volume directly affects acoustic characteristics like frequency response and SPL. A tolerance of ±10% is usually acceptable, but matching the specified volume as closely as possible ensures consistent results.

Prototyping with the enclosure in place is essential. Testing in free air can yield misleading results and overlook reliability issues. Consider enclosure design early in the development process. Collaboration between mechanical and electrical teams helps balance acoustic performance, device size, and manufacturing constraints.

Speaker Mounting and Grille Considerations

For a rear enclosure to perform as intended, the back of the speaker must be isolated from the front. Unintended leaks reduce back pressure, cause attenuation, and can alter the frequency response, which compromises the role of the rear enclosure. Gaskets, precision fits, and adhesives are common solutions for maintaining separation. When vents are included, their size, shape, and placement must be carefully controlled to maintain predictable acoustic behavior. Whether sealed or vented, airflow must be managed consistently.

The front grille should protect the diaphragm without obstructing its performance. We recommend an open-area ratio of at least 20% to avoid significant losses, and 40% or more for performance-critical designs. Provide sufficient clearance between the diaphragm and grille so they cannot contact during peak excursion, accounting for manufacturing tolerances and any grille flex. Thinner materials with rounded perforations further reduce turbulence and distortion.

Conclusion and Additional Resources

Rear enclosures play a critical role in the performance, reliability, and longevity of many miniature speaker designs. Whether required for mechanical stability or used to fine-tune acoustic output, the enclosure should be treated as an integral part of the speaker system, not an afterthought.

Understanding when a rear enclosure is necessary and designing it appropriately can prevent costly failures, ensure datasheet-level performance, and accelerate product development timelines. Careful attention to datasheet conditions, enclosure volume, sealing quality, and early integration will lead to more successful outcomes in both prototyping and production.

For qualifying projects, Same Sky offers bespoke audio design and simulation services as well as speaker enclosure design services for custom rear enclosure development. Our engineering team can help design an enclosure that not only meets acoustic requirements but integrates seamlessly into your product’s mechanical architecture.

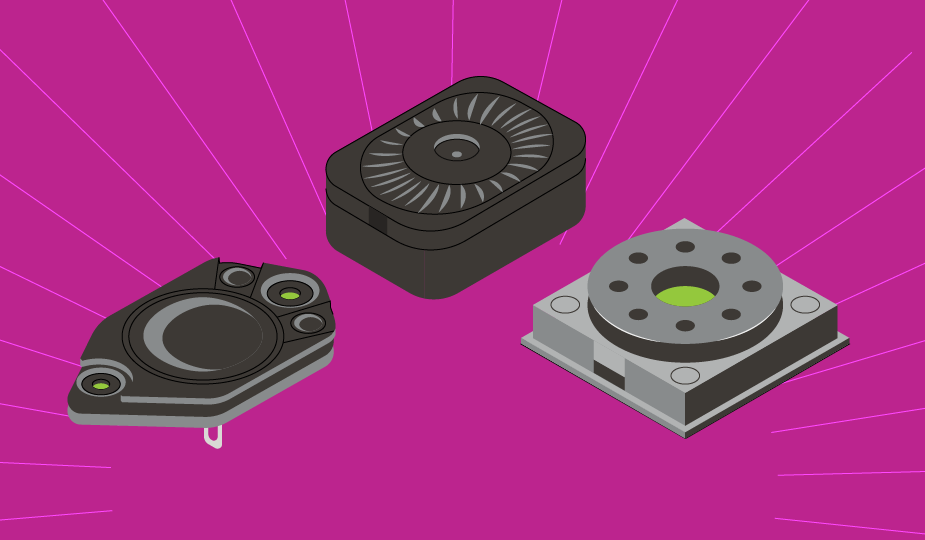

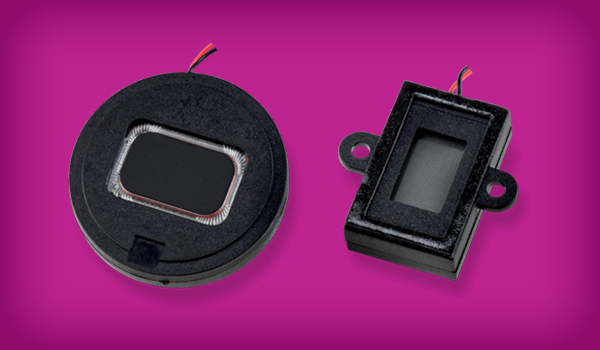

For applications where designing a rear enclosure isn’t feasible, we also offer a selection of miniature speakers with integrated rear enclosures. See our enclosed speaker options to explore available models. And for customers handling their own integration, we offer additional guidance in our posts:

Our team is here to help you bring your design to life, efficiently, reliably, and with confidence.

Key Takeaways

- All speakers work by driving a diaphragm with a voice coil, but mini and micro speakers are more reliant on enclosure design due to thinner suspensions.

- A rear enclosure provides back pressure, shapes frequency response, and ensures mechanical stability, making it critical in miniature speaker designs.

- Some miniature speakers require a rear enclosure to prevent over-excursion, protect components, and maintain proper performance.

- Even when not required, enclosures improve low-frequency output, reduce distortion, and allow performance tuning for both small and standard speakers.

- Datasheet conditions and enclosure volume must be followed closely, with prototyping done using the enclosure to avoid misleading results.

- Proper sealing is essential to isolate front and rear chambers, prevent leaks, and maintain consistent acoustic behavior.

- Grille design should balance protection and performance with sufficient open area, clearance, and low-distortion features.

- Well-designed enclosures extend reliability, ensure datasheet-level performance, and reduce costly failures or redesigns.